Seafood and Agricultural Product Steamer

This is a steamer for boiling scallops. It has over 30 years of history.

In the beginning, it could only process less than a ton of scallops per hour. Now, we make steamers that can process up to somewhere around 15 tons per hour.

We not only take into account the characteristics and the properties of scallops but also those that derive from production location and methods to create heating conditions that are the most effective.

This technology is also applied currently in large-scale soybean and kidney bean processing plants.

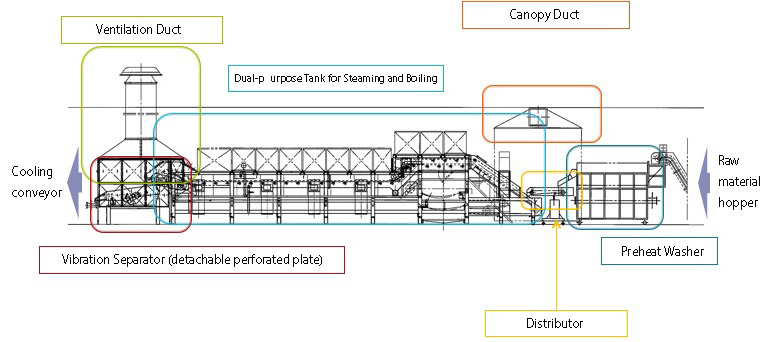

Line External View

Layout

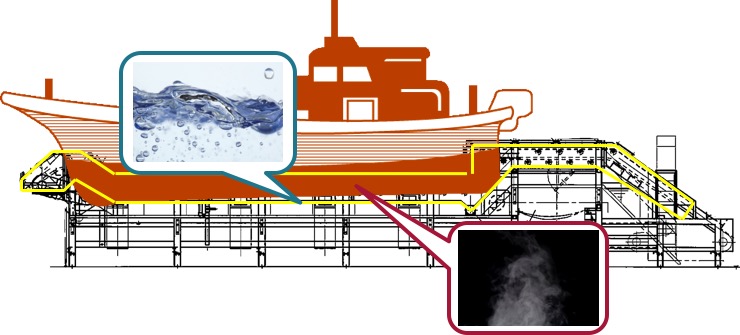

There is not only the standard mountain-shaped model but also a boat-shaped model, which our company was first to develop around 20 years ago.

- The boat-shaped model

- from some 20 years ago; we were the first!

- A dual cooker− both a steamer and boiler!

- The older mountain-shaped model was only able to steam food due to its shape. However, the boat-shaped model can hold hot water which allows it to steam as well as boil the food.

Steamer

These are the benefits of having scallops cooked in this steamer rather than the standard boiler.

Automatic Fixed Amount Conveyor

It automatically feeds raw materials according to the production volume. In order to produce consistent products, we have to give a consistent supply of raw materials.

This device features an automatic feeder and a raw material hopper to give a fixed amount of supply to the preheating washer according to the set speed of the bucket conveyor.

Raw Material Hopper

Preheating Washer

It washes and preheats raw materials at the same time. This feature has a turning drum in the water tank where it uses steam to keep the water at a consistent temperature and opens the shells by washing them in the warm water.

The waste drain screw conveyor helps keep the water clean to reduce the number of water changes significantly. It improves cleaning performance and productivity and saves energy.

Distributor

In order to produce consistent products, we have to place the raw materials evenly on the net conveyor.

This feature was developed mainly for the scallops. We installed a chute that vibrates left and right over the net conveyor to evenly place the supplies.

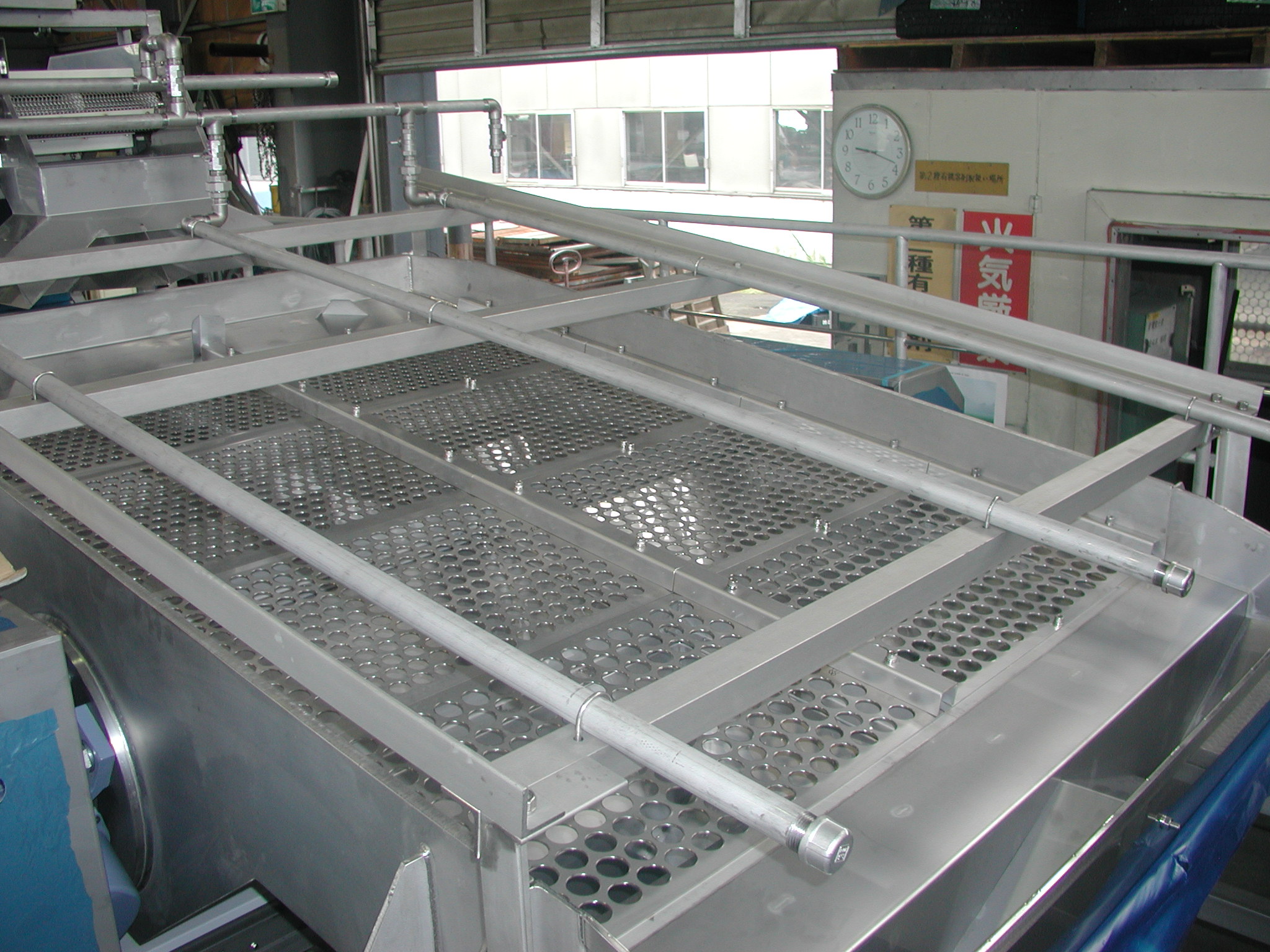

Separator

This feature is for separating the scallop shells and the flesh. The flesh separated at the vibrating chute goes through the cooling conveyor into the tank and is collected into the shell sorting drain conveyor.

Sorter

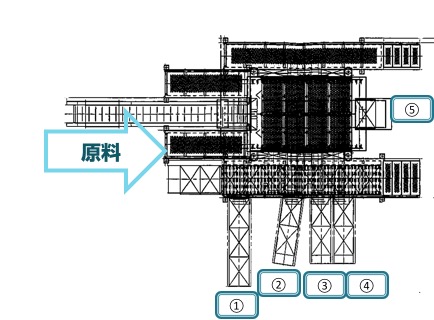

Application to Agricultural Products

This is an example of when it was applied to the soybean and kidney bean processing plant.

System-related Products

- Vibrating Sorter

- Cooling conveyor,

- sorting conveyor,

- lining conveyor,

- connecting conveyor,

- shell crusher,

- duct facility,

- and more.